The fluid management service provided by Bantleon allows you to once again focus on your core business.

The service from Bantleon includes complete support and maintenance of fluids. Regular monitoring of your cooling lubricants and other media helps you make savings, while also guaranteeing a constant, long-term quality standard.

Overview of our services:

Cooling lubricant support

We optimise the replacement intervals on your machines.

This not reduces the environmental impact, but also helps save you money.

Cooling lubricant replacement

We change your cooling lubricants for you using our expertise.

This allows the service life of cooling lubricants to be optimised.

TRGS 611

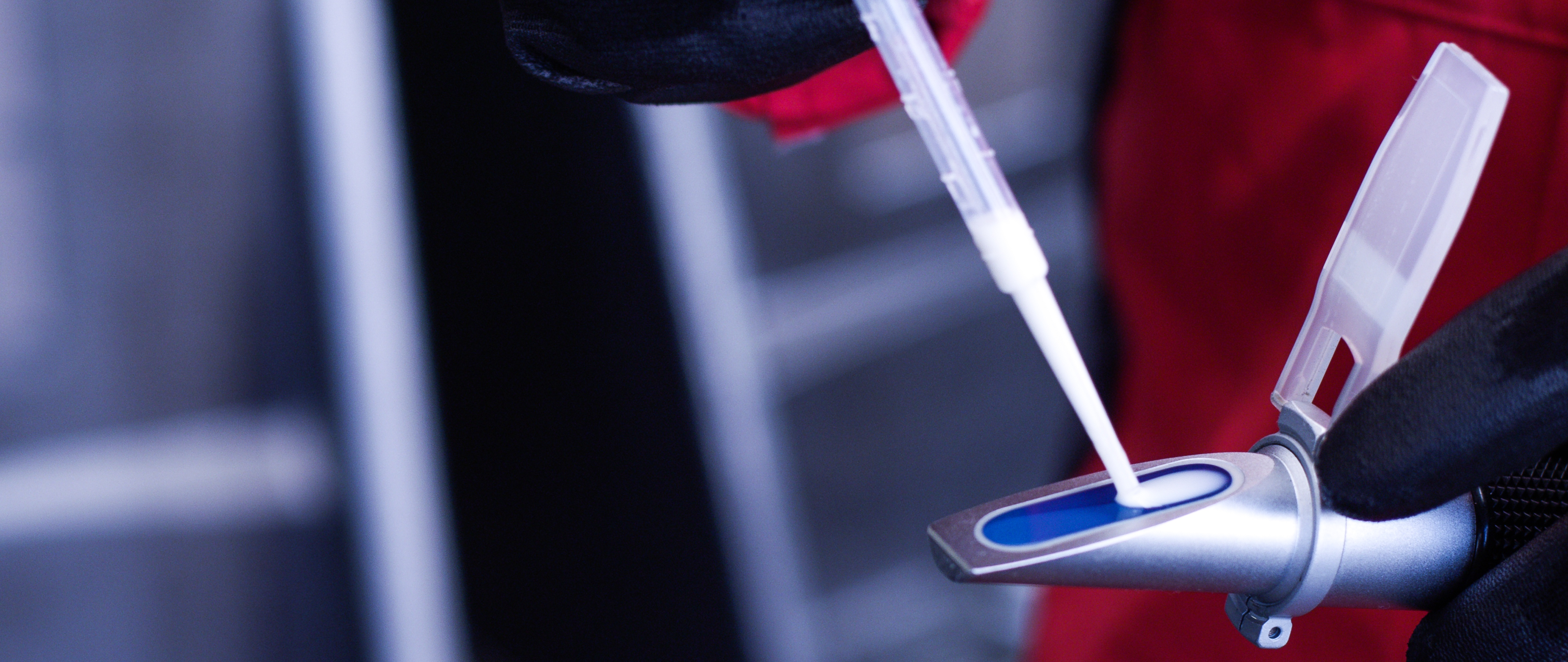

The legislator stipulates weekly measurements of the pH value, nitrite content, as well as the concentration of cooling lubricants.

We’re more than happy to perform these measurements for you.

Lubrication and oil service

To ensure that your machines are both available and ready for use at all times, we obviously also take care of the lubrication and oil service.

For example hydraulic and bedway oils, greases and radiator antifreeze.

Filter management

Our qualified Bantleon employees are also more than happy to perform the replacement of the various filter media used in your equipment.

Conservation and cleaning

Our staff are also happy to perform a thorough service of your conservation tanks and cleaning systems, as well as the requisite measurements.

B.FLUID - Digital fluid management

B.FLUID is our exclusive digital solution within the framework of BANTLEON fluid management. The system, developed in-house, enables seamless data collection, a central machine overview, and simple, legally compliant implementation of TRGS 611.

All data is securely archived, transparently processed, and available at any time via app and web portal. Early warning messages, individual connection, and personal support ensure maximum process reliability and efficiency.

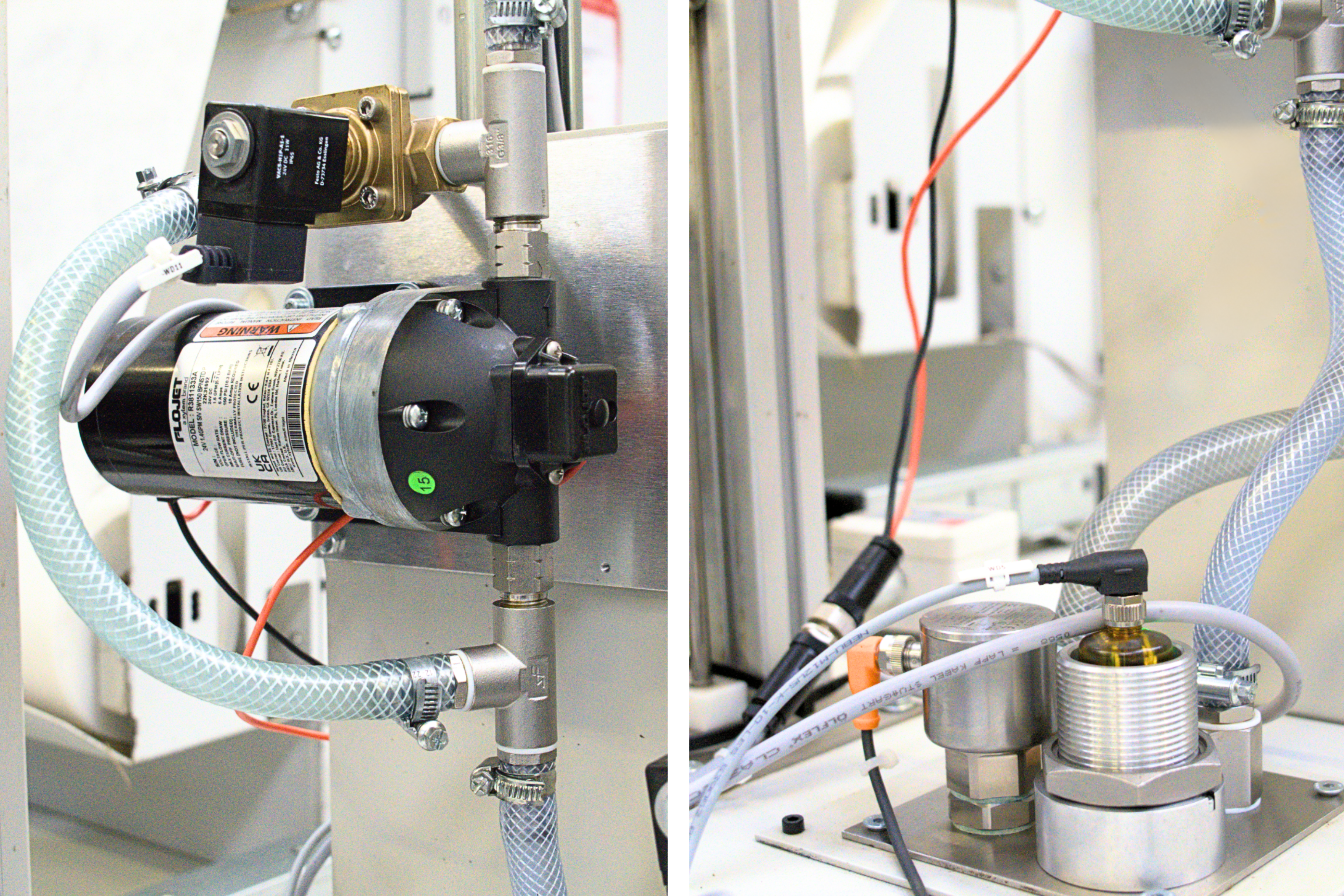

CUMA – Fully automated cooling lubricant management

CUMA stands for Cutting Fluid Manager. The system continuously measures and monitors the concentration, pH value, and conductivity of your emulsion – fully automatically and precisely. CUMA independently regulates the refilling with water and concentrate, ensuring that the cooling lubricant tank is always optimally filled.

The web-based software allows you to keep track of all data, consumption values, and quality parameters – individually adjustable and accessible at any time. Compatible with Bantleon's water-miscible cooling lubricants – for comprehensive service from a single source. For more information, please contact our experts.