As a certified specialist pursuant to the Water Resources Act (WHG), BANTLEON supports you with consulting, planning and implementation of innovative and legally compliant storage and tank technology for handling media deemed hazardous to water. We offer everything from the raw concept all the way to commissioning, including legally watertight documentation. This also fits in with the system partner approach of Hermann Bantleon GmbH. As a certified specialist pursuant to the Water Resources Act (WHG), we ensure that everything is legally compliant, from planning, through implementation, all the way up to maintenance in close coordination with the responsible authorities and experts.

Oil and tank storage facilities, central media supply (fresh oils, fuels, operating materials)

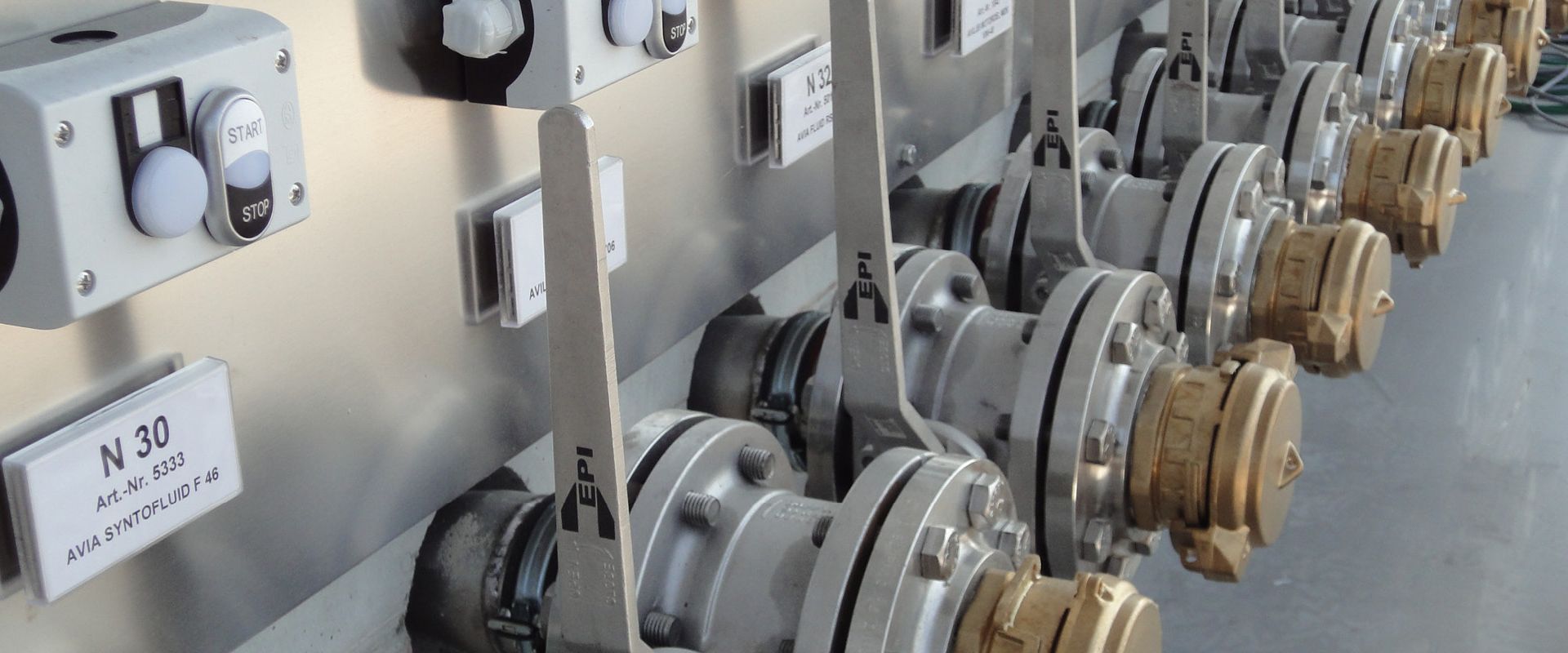

Demand-driven supply of assembly areas or filling stations on the customer's premises is one of our core areas of expertise. We make sure you receive the right medium in the right quantity at the right location.

Our portfolio of services in this area ranges from basic tanks, through the necessary pipework, all the way to the pump nozzle, including planning and implementation of a custom system.

The benefits for you:

Delivery capacities and operating pressures matched precisely to your requirements

Use of high-grade and fail-safe system components

Compliance with legal stipulations, leading to a high degree of system safety and reliability

Modern control system based on customer wishes, including communication with the ERP system and logging of the filling processes as a quality assurance tool

Extraction systems (emulsion mist, oil mist, exhaust gas) and chip processing plants

In close cooperation with longstanding partners and suppliers, we provide support for planning and procurement of extraction systems for oil mists, emulsion mists and exhaust gases. These systems excel through their energy efficiency, heat recovery and durability, as well as their low maintenance costs.

Significant volumes of cooling lubricant can be recovered/recycled using chip processing plants. This in turn helps lower consumption, costs and also disposal volumes in the long term.

Grease supply / grease handling

In the field of grease supply, we support our customers with high-grade equipment in order to implement lubrication of machines and filling of central grease supply systems simply, at the desired speed and without any niggling issues.

The benefits for you:

Customer-specific solutions

Simplified and clean handling of containers

Optimised lubrication solutions

Replacing the evaporation and discharge losses of the cooling lubricants in individually filled production machines and central supply systems

Innovative solutions in the field of lubricant logistics, comprising a tank, pipework and metering units, support our customers throughout the added value chain.

Digital monitoring solutions help secure process reliability and corresponding documentation reliability.

» Read more

The benefits for you:

Stable cooling lubricant concentration for high quality assurance

Minimised personnel costs for filling the machines

Simplified handling of the containers

Avoidance of machine downtimes

Maintaining and repairing tank facilities

As a certified specialist pursuant to the Water Resources Act (WHG), we provide support during both planning and implementation of corresponding systems for handling media deemed hazardous to water.

The benefits for you:

Fulfilment of legal requirements pursuant to the Plant Regulations for Handling of Substances Hazardous to Water (AwSV)

Legally compliant repair & maintenance, also of calibrated installations

Legally compliant system documentation