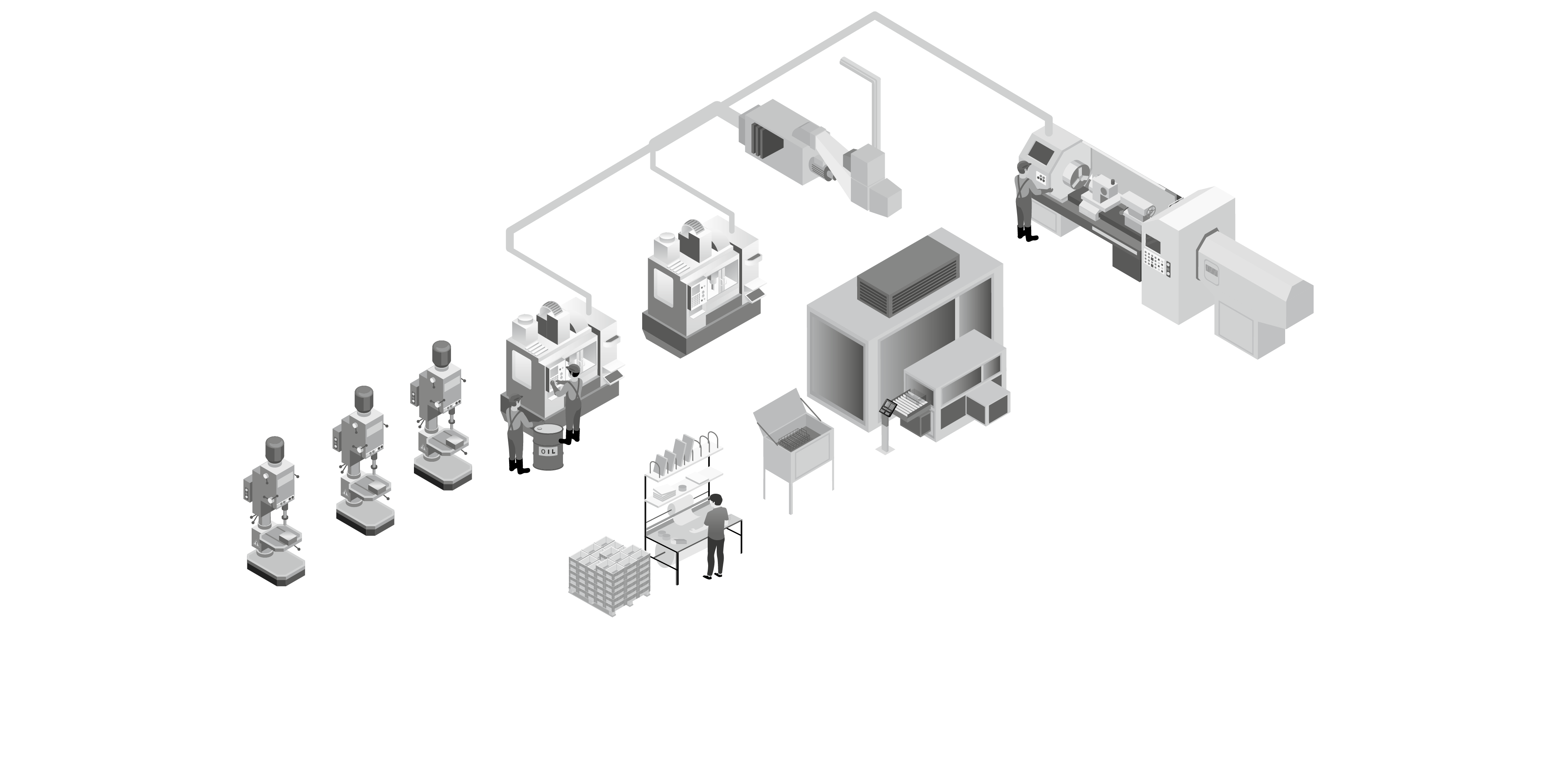

Processes such as drilling, turning, milling or grinding, yet also punching or forming play a key part in metalworking operations. These are then also affected by influencing factors such as materials, machine and systems engineering, geometry or temperature and cutting speed. Many factors determine the specific options available, as well as the special challenges associated with metalworking/machining. Lubricants make a sustainable contribution to process reliability.

Reducing friction, wear and temperature in the process has a significant impact on productivity and resource conservation. Water-miscible and non-water-miscible cooling lubricants, developed with a keen eye on important parameters such as performance / quality, climate protection / occupational health and safety are used here.

Areas of application in metal cutting

Together with our partner AFS Airfiltersysteme, we support you in planning and implementing sustainable solutions for extraction and air purification in your production. >> read more

Whether for cutting or non-cutting metal processing: Choose from a wide range of tried-and-tested cooling lubricants or let us develop your very special solution. >> read more

Depending on the existing system technology or the building material to be cleaned, BANTLEON offers the ideal cleaning medium. >> read more

Increasing demands on the surface properties of components require process-reliable solutions. With liquid and dry preservation from BANTLEON you create security across the entire value chain. >> read more

BANTLEON develops tailor-made solutions for corrosion protection and cleanliness of your packaged goods. Of course, we take into account all the requirements of your process chain. >> read more

With BANTLEON Fluid Management 4.0 you can concentrate on your core business again. The BANTLEON service includes complete care, maintenance and documentation. >> read more